Ready Mix Concrete

Ready Mix Concrete

At Chaney Enterprises, we provide premium ready-mix concrete tailored to meet the unique demands of your construction projects. Our ready-mix concrete is meticulously crafted from a blend of cement, aggregates, water, and specialized additives, ensuring the highest quality and performance.

Utilizing state-of-the-art production and testing technology, we offer a diverse range of concrete mixes with strengths ranging from 50 to over 10,000 PSI. With more than 1,500 custom mix designs, we are equipped to satisfy any project specification.

Commonly Requested Mixes:

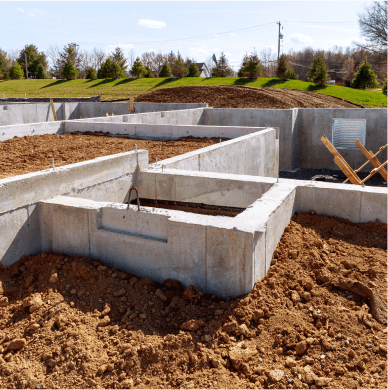

Footer Mix

Ideal for foundations and structural footings.

Wall Mix

Perfect for durable and resilient wall construction.

Interior Slab Mix

Designed for indoor flooring with a smooth finish.

Exterior Slab Mix

Built to withstand outdoor conditions with enhanced durability.

Admixtures & Fibers:

Enhance the performance of your concrete with our range of admixtures and fibers. These additives provide various benefits from increased strength to improved durability.

Popular Admixtures:

- Every Day Admix: Standard admixture for everyday applications.

- Water Reducer: Reduces water content while maintaining workability.

- High Range Water Reducer(Super Plasticizer): Allows for high slump mixes with superior flowability.

- Air Entrainment: Adds air bubbles for better freeze-thaw resistance, essential for exterior concrete.

- Carbon Cure: Reduces carbon footprint by utilizing captured CO2.

- Seasonal Admixes:

- Accelerator (Winter): Speeds up curing in cold conditions.

- Retarder / Hydration Stabilizer (Summer): Slows down setting to prevent premature drying in hot weather.

- Ice (Summer): Cool down the mix during high temperatures.

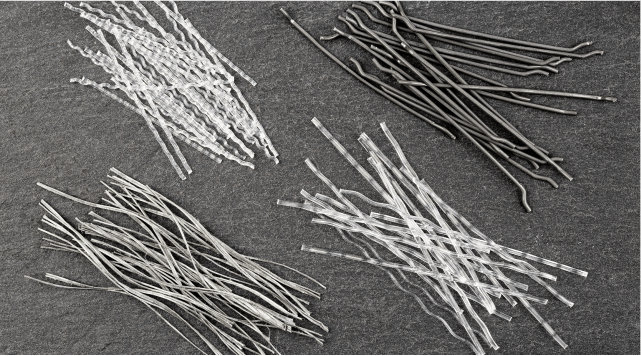

Fibers:

Incorporate fibers to minimize shrinkage and cracking. Fibers can replace traditional reinforcement methods such as welded wire mesh and rebar.

Specialty Admixtures:

- Shrinkage Reducing Admix: Decreases concrete shrinkage.

- Corrosion Inhibitor: Protects rebar from internal corrosion.

- Rheology Modifying Admix: Enhances the workability of pervious concerte.

- Viscosity Modifying Admix: Improves the consistency of Self Consolidating Concrete.

Specialty Concrete

Ever Concrete Series

Reduce the embodied carbon of your project with our newest line of less carbon-intensive concrete.

Learn more about the Ever Series >

Colored Concrete

Green cart paths? Red patio? You dream it, we can color it.

Download our Integral Color Chart >

Flowable Fill

Cut costs and simplify construction with controlled low-strength material that flows into place, requiring no compaction and ensuring easy backflow.

Request a Quote >

Pervious Concrete

A unique blend of concrete with interconnected holes that allow water to flow through, while providing a durable paving surface. Watch the water flow at 300-400 inches per hour and provide insane filtration. Talk about stormwater management!

Request a Quote >

Self-Consolidating Concrete

Self-Consolidating Concrete (SCC) is a unique mix that is designed to flow and solidify under its own weight. It flows into the most heavily reinforced areas without any vibration, all while retaining the strength and durability of traditional concrete.

Request a Quote >

Insulated Concrete Forms

Insulated Concrete Forms (ICFs) are insulated foam blocks that lock into place and are then filled with reinforced concrete to create high-strength walls. Concrete walls protect against adverse weather conditions, deter termites, lower heating/cooling costs, and are easy to install and maintain.

Request a Quote >

Mobile Concrete Plants

Built at your location, portable concrete plants eliminate the need to import building materials and allow for on-demand, high-quality production. Best suited for large projects with high-volume demand.

Get In Touch >